Our Redi-Rock installations near you

Seeing is believing!

Visiting a Redi-Rock installation site is the best way to give you a true sense of these retaining walls' size, quality, and elegance. This interactive map will help you locate a Redi-Rock installation near you.

Whether you're looking to touch the block, see it in the real world, or be inspired, we hope this tool serves you well.

Redi-Rock overview

J&R Precast - One of New England's leading producers and suppliers of Redi-Rock.

Redi-Rock is an industry-leading interlocking retaining wall system for building tall gravity walls and even taller reinforced walls.

The Redi-Rock retaining and free-standing wall systems utilize an innovative and unique series of knob and groove technology resulting in a self-aligning system.

This engineered solution allows the entire structure to interlock with each other minimizing excavation on-site and reducing the need to use expensive geo-grid or tie-back systems. The J&R Precast Redi-Rock system features a unique and attractive Ledgestone and Split Limestone appearance that mimics the look of natural stone.

All J&R precast Redi-Rock products are manufactured to meet or exceed all state and ASTM standards.

J&R Precast Redi-Rock comes in three sizes and two faces - 60", 41", & 28"

Ledgestone

Limestone

Redi-Rock Advantages

- Fast and easy installation

- Reduced labor costs

- Less excavation is required, and less space is needed for installation

- Versatile - Installs where small block systems are not practical

- Leverages machine labor and a small crew giving Redi-Rock a distinct advantage in performance and installation costs.

Latest Post

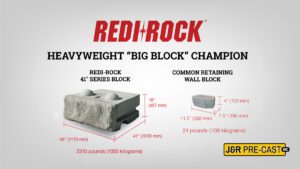

4 Reasons Why Redi-Rock is the Heavyweight Champion of Retaining Wall Systems

Redi-Rock “Big Blocks” come in various sizes, but on average, they weigh about 1 ton each. In comparison, smaller blocks typically weigh between 20 and 120 lbs, highlighting why these are referred to as “big.” Our 2,000-pound blocks perform like…

Continue Reading »Redi-Rock applications

Where do you use Redi-Rock systems?

Redi-Rock gravity walls and retaining walls were invented to serve the need for an architecturally pleasing yet cost-effective structural retaining wall solution – perfect for the New England terrain and climate.

Redi-Rock applications are not limited to just “standard” retaining walls. Use Redi-Rock from J&R Precast as a superior retaining wall system specifically developed to meet the most demanding structural needs for projects like:

Why do designers & contractors choose Redi-Rock?

Designers love the aesthetics, functionality, and flexibility that Redi-Rock provides

For contractors, Redi-Rock looks excellent and is easy and more economical to install than most wall systems.

Residential

- Driveways

- Decorative

- Waterfront, waterway, and shore protection

- Enhanced landscaping, patio, yard expansion

- Garage Under/Wing Walls

Commercial

- Golf Courses

- Parks and Recreation

- Parking lots

- Walkways

- Bridges/Overpasses

- Culverts

- Headwalls

Industrial

- Retail or Box Stores

- Housing Developments

- Free Standing Walls

- Building Security

- Manufacturing Facilities

Municipal

- Airports

- Military

- Cemeteries

- Highway Retentions

- Above grade guardrail systems

- Railroad and waterway

Redi-Rock product lines

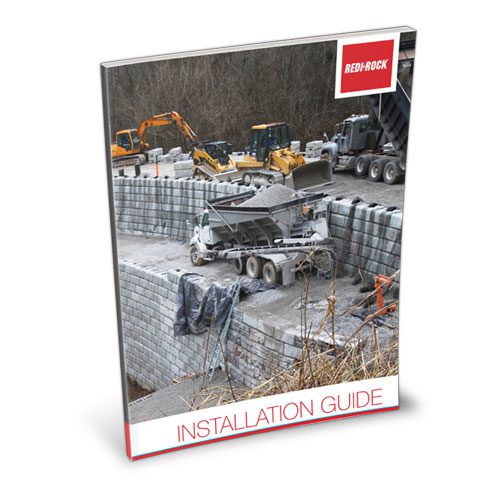

Redi-Rock installation

Before you start your project or look through pages of PDFs, call or email J&R Precast. Once we understand your project, our engineers can work with your designers, engineers, and contractors to help you determine the best and most effective way to complete your retaining wall project saving you hours of time and energy.

How do you install Redi-Rock?

A high-level overview of the basic installation process for Redi-Rock retaining wall systems

- Site preparation and location

- Ground Preparation to Create a Leveling Pad Placement

- Backfill Leveling Pad

- Excavate to the lines and grades on the construction drawing

- Install block units. Position blocks to be offset from seams of blocks below. Blocks shall be placed fully forward so the knob and groove are engaged.

- Check each block for proper alignment and level. Backfill to 12-inch width behind the block with free-draining backfill.

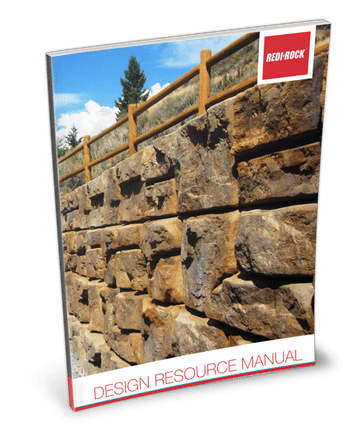

Different site preparations and conditions can make installation more or less complicated. For more in-depth installation instructions, you will want to review the PDF Instruction Manuals available for download here.

Additional Installation Videos

You want your walls to last forever, and mastering this critical first step is where you need to start! Watch the video to see a step-by-step overview of how to install this critical component.

Retaining Wall FAQs

Building a retaining wall may seem simple, but it involves important considerations to ensure stability and durability:

- Soil Conditions & Bearing Capacity: The wall must be designed to handle the weight of the soil and other loads.

- Slope & Pressure: Factors such as toe slopes, surcharges on the wall, and hydraulic pressure must be accounted for.

- Environmental Considerations: Freeze-thaw cycles, wind loads (especially if a fence is needed), and water drainage impact the wall’s performance.

- Safety Factors: Overturning, sliding resistance, and global stability must be evaluated to prevent failure.

Working with experienced materials providers like J&R Pre-Cast helps ensure these principles are addressed for a successful project.

When choosing retaining wall blocks or other materials, consider the following key factors:

- Material Options: Retaining walls can be built using materials like poured concrete, boulders, stone (rip rap), small or large blocks, pressure-treated timbers, and railroad timbers. Each material varies in durability and structural integrity.

- Structural Integrity: This is critical for retaining walls. Different materials offer different levels of strength:

- Boulders/Granite: Naturally strong but difficult to engineer and place.

- Small Blocks: Made using a dry-cast concrete process, which has a shorter lifespan.

- Large Blocks: Made using a wet-cast process, offering greater longevity.

- Wood Timbers: Pressure-treated wood is no longer manufactured to last as long in the ground as it once did.

- Longevity: The lifespan of retaining wall materials varies:

- Some materials last a lifetime (like Redi-Rock wet-cast concrete).

- Others may only last 5 to 15 years (like dry-cast blocks or wood).

Retaining wall projects can be labor-intensive and costly, so consider the long-term value of materials with greater longevity to avoid future rebuilds.

When planning your retaining wall, keep these aesthetic factors in mind:

- Proper Scale: The size of your retaining wall blocks is important for the overall look. Using oversized blocks in a small space or small blocks in a large space can make the wall feel out of place. Choose a block size that fits the scale of your space for a balanced appearance.

- Texture & Color: While many textures are available, color options for wet-cast concrete products can be limited. The texture and color you choose will impact the wall’s final look, so select a product that complements your space. Our blocks only come in concrete gray.

Additionally, keep these functional aspects in mind:

- Soil & Water Conditions: Ensure the soil where your wall will sit is stable. If you encounter clay or peat, consult an engineer. Most walls require a solid footing—compacted ¾” stone is often sufficient, but some projects may require a concrete footing depending on the wall’s height and load.

- Water Drainage: Proper drainage is essential. Water is a retaining wall’s biggest enemy, and hydraulic pressure from water buildup can cause damage. Incorporate weep holes or other drainage solutions to allow water to escape and prevent pressure from building up behind the wall.

A retaining wall's cost depends on the materials and labor involved. Here are key factors to consider:

- Labor Costs: Materials like timbers or small dry-cast concrete blocks may have lower costs per square foot, but they are labor-intensive to install, increasing overall costs.

- Material Value: While large wet-cast concrete blocks may have a higher upfront material cost, they cover more square feet per block, require less labor (since they are machine set), and offer long-term durability.

- Longevity: Wet-cast concrete blocks are designed to last a lifetime, providing better value in the long run by reducing the need for future repairs or replacements.

In summary, retaining wall costs are more about the value you choose—opt for materials that minimize labor and offer lasting durability for the best investment.